Bahan magnet permanen Alnico ora bisa dirancang minangka bagean struktur amarga fitur kekuatan mekanik sing kurang, kekerasan dhuwur, brittleness, lan kemampuan mesin sing kurang.Mung sawetara grinding utawa EDM sing bisa digunakake sajrone proses, cara liya kaya forging lan mesin liyane ora bisa digunakake.

AlNiCo utamané diprodhuksi dening cara casting.Kajaba iku, metalurgi bubuk uga bisa digunakake kanggo nggawe magnet sintered, sing nduweni kinerja sing rada murah.Cast AlNiCo bisa diproses dadi macem-macem ukuran lan wangun nalika produk AlNiCo sintered utamané cilik-ukuran.Lan workpieces saka AlNiCo sintered duwe toleransi dimensi sing luwih apik, sifat Magnetik sing dicokot luwih murah nanging machinability luwih.

Ing kauntungan saka wesi sembrani AlNiCo punika remanence dhuwur (nganti 1.35T), nanging kekurangan iku pasukan coercive banget kurang (biasane kurang saka 160kA / m), lan kurva demagnetization non linear, supaya AlNiCo punika sembrani gampang kanggo. dadi magnet lan uga gampang demagnetized.Nalika ngrancang sirkuit magnetik lan manufaktur piranti, perhatian khusus kudu dibayar lan magnet kudu stabil sadurunge.Kanggo ngindhari demagnetisasi sing ora bisa dibatalake utawa distorsi distribusi kapadhetan fluks magnetik, dilarang banget kanggo kontak karo zat ferromagnetik nalika digunakake.

Cast AlNiCo sembrani permanen nduweni koefisien suhu paling bisa dibalèkaké antarane bahan magnet permanen, suhu apa bisa tekan nganti 525 ° C, lan suhu Curie kanggo 860 ° C, kang materi sembrani permanen karo titik Curie paling dhuwur.Amarga stabilitas suhu sing apik lan stabilitas tuwa, magnet AlNiCo uga ditrapake ing motor, instrumen, piranti elektroakustik, lan mesin magnetik, lsp.

Daftar Kelas Magnet AlNiCo

| kelas) | Amerika Standar | Br | Hcb | BH maks | Kapadhetan | Koefisien suhu sing bisa dibalik | Koefisien suhu sing bisa dibalik | Suhu Curie TC | Suhu operasi maksimum TW | pangandikan | |||

| mT | Gs | KA/m | Oe | KJ/m³ | MGOe | 6.9 | % / ℃ | % / ℃ | ℃ | ℃ | |||

| LN10 | ALNICO3 | 600 | 6000 | 40 | 500 | 10 | 1.2 | 7.2 | -0.03 | -0.02 | 810 | 450 | Isotropik

|

| LNG13 | ALNICO2 | 700 | 7000 | 48 | 600 | 12.8 | 1.6 | 7.3 | -0.03 | +0.02 | 810 | 450 | |

| LNGT18 | ALNICO8 | 580 | 5800 | 100 | 1250 | 18 | 2.2 | 7.3 | -0,025 | +0.02 | 860 | 550 | |

| LNG37 | ALNICO5 | 1200 | 12000 | 48 | 600 | 44 | 4.65 | 7.3 | -0.02 | +0.02 | 850 | 525 | anisotropi |

| LNG40 | ALNICO5 | 1250 | 12500 | 48 | 600 | 40 | 5 | 7.3 | -0.02 | +0.02 | 850 | 525 | |

| LNG44 | ALNICO5 | 1250 | 12500 | 52 | 650 | 37 | 5.5 | 7.3 | -0.02 | +0.02 | 850 | 525 | |

| LNG52 | ALNICO5DG | 1300 | 13000 | 56 | 700 | 52 | 6.5 | 7.3 | -0.02 | +0.02 | 850 | 525 | |

| LNG60 | ALNICO5-7 | 1350 | 13500 | 59 | 740 | 60 | 7.5 | 7.3 | -0.02 | +0.02 | 850 | 525 | |

| LNGT28 | ALNICO6 | 1000 | 10000 | 57.6 | 720 | 28 | 3.5 | 7.3 | -0.02 | +0.03 | 850 | 525 | |

| LNGT36J | ALNICO8HC | 700 | 7000 | 140 | 1750 | 36 | 4.5 | 7.3 | -0,025 | +0.02 | 860 | 550 | |

| LNGT38 | ALNICO8 | 800 | 8000 | 110 | 1380 | 38 | 4.75 | 7.3 | -0,025 | +0.02 | 860 | 550 | |

| LNGT40 | ALNICO8 | 820 | 8200 | 110 | 1380 | 40 | 5 | 7.3 | -0,025 | +0.02 | 860 | 550 | |

| LNGT60 | ALNICO9 | 950 | 9500 | 110 | 1380 | 60 | 7.5 | 7.3 | -0,025 | +0.02 | 860 | 550 | |

| LNGT72 | ALNICO9 | 1050 | 10500 | 112 | 1400 | 72 | 9 | 7.3 | -0,025 | +0.02 | 860 | 550 | |

| Sifat fisik saka AlNiCo | |

| Paramèter | AlNiCo |

| Suhu Curie (℃) | 760-890 |

| Suhu operasi maksimum (℃) | 450-600 |

| Kekerasan Vickers Hv (MPa) | 520-630 |

| Kapadhetan (g/cm³) | 6.9-7.3 |

| Resistivitas (μΩ · cm) | 47-54 |

| Koefisien Suhu Br(%/℃) | 0,025~-0,02 |

| Koefisien suhu iHc(%/℃) | 0.01~0.03 |

| Kekuatan tarik (N/mm) | <100 |

| Kekuatan putus transversal (N/mm) | 300 |

Aplikasi

Magnet AlNiCo nduweni kinerja sing stabil lan kualitas apik.Utamane digunakake ing meter banyu, sensor, tabung elektronik, tabung gelombang lelungan, radar, bagean nyedhot, kopling lan bantalan, motor, relay, piranti kontrol, generator, jig, panrima, telpon, switch reed, speaker, alat genggam, ilmiah. lan produk pendidikan, lsp.

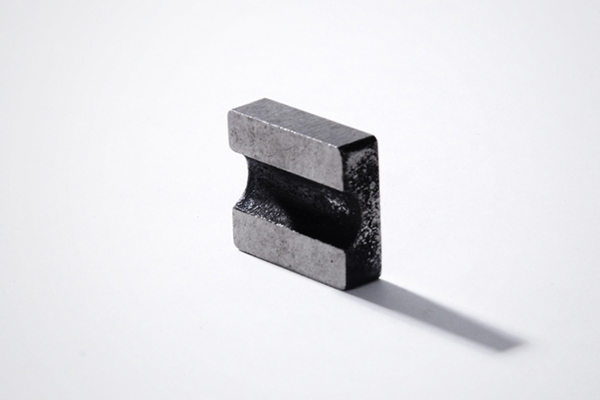

Tampilan Gambar